Overall strategy of the Work Plan

The BASMATI project approach must be considered as a generic approach for the development of functional printing inks containing nanoparticles of existing functional materials. Evidently, this kind of development work should be strongly directed by the requirements concerning functional product properties and printing behaviour. Therefore, in each development phase of the project, focus should be both on the required functional product properties of the final application, and on the properties related to the printing behaviour of the ink. Too much one-sided focus on the printing behaviour may lead to failure, e.g. inks that can be printed very well, but with functional properties not meeting targets.

The first step in the project is the lab-scale synthesis of these nanomaterials by different process routes. In order to enhance their functional properties or to tune their suspension behaviour in the ink, further functionalization may be required. In some cases this functionalization is an integrated part of the synthesis. If not, it needs to be considered as a separated task. At the end of this work package the most appropriate process routes need to be selected for up-scaling to the pilot line. Here, the input of experienced industrial partners is essential.

When the functionalized nanomaterials have been produced in lab-scale quantities, the ink formulation development starts. First, a large number of solvents, binders and additives are screened to build a substantial knowledge library on the influence of these ink ingredients on the functional properties of the inks and their printability. Using this knowledge the ink formulations are optimized at lab-scale for each printing technology under consideration. A direct feedback loop between the ink formulation development and the nanomaterial development is essential.

Once the functional inks are available, their potential needs to be assessed in a demonstrator application.

In order to prove the industrial feasibility of the production of functional inks, it is necessary to up-scale the most appropriate lab-scale processes for synthesis and functionalization, and for ink formulation to pilot-scale. Obviously, the economic feasibility is also addressed, based on the experience of industrial partners.

Nano-safety issues and the potential harmful impact of nanomaterials and inks containing those nanomaterials on humans and on the environment are to be addressed. The goal is to provide recommendations for best practices and to incorporate nano-safety into the design of the pilot

lines (safe-by-design).

The BASMATI project follows this generic approach to develop conductive and electrochemical inks containing metallic and polyatomic nanomaterials at lab- and pilot scale that are applied in different printing technologies. The demonstrator application is a printed battery.

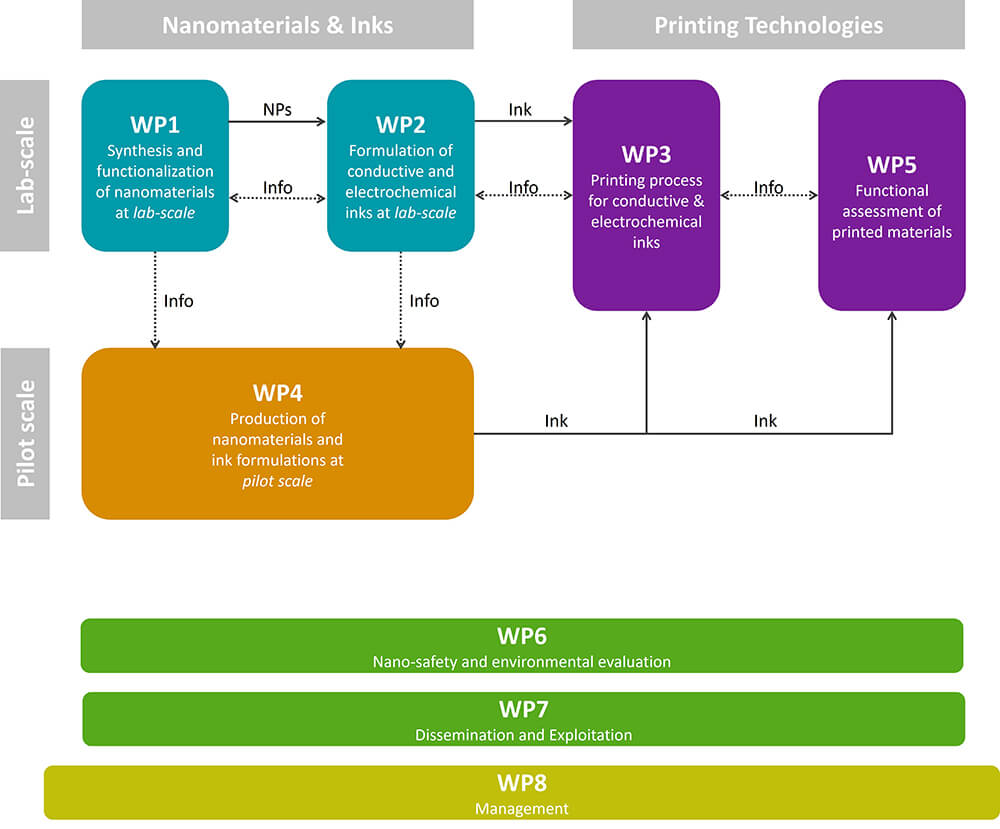

The BASMATI work plan is divided into 5 technical work packages, one nano-safety and environmental work package, one work package dealing with dissemination and exploitation, and one coordination work package. The work plan, with material and information flow, is schematically represented below: