- Details

New positive result of working together on the currently ongoing BASMATI project of the European commission can be seen. microdrop Technologies is succesfully printing pattern with copper ink, developed by Genes'Ink.

- Details

On the 23rd of November 2016, BASMATI project organises an industrial workshop in Barcelona. It gathers companies and research institutes from all over Europe working in the field of printed electronics, battery development and advanced materials. Speakers from the Organic Electronics Association, CEA, Varta and Umicore have already confirmed their attendance. Much more is still to come!

Click here to download the draft agenda.

Click here to register!

The event is free and open to every person willing to meet and exchange with professionals working in this very innovative and promising sector.

Free Webinar: The Road to Commercialiyation of Thin-film, Flexible and Printed Batteries by IDTechEx

- Details

On the 14th of June, Dr. Xiaoxi He, Technical Analyst at IDTechEx will hold a free webinar of 40 minutes at 9:30 GMT+1. He will concentrate on the size of batteries, that need to become smaller and smaller. In addition, batteries need to lower their production costs and have easier manufacturing methods.

BASMATI project, developing a new value chain for conductive inks, is strongly interested into this topic and its members will follow this open event.

To register, click here.

- Details

LEITAT and VARTA presented the Basmati Project during LOPEC 2016. Below you can find some highlights.

- Details

IDTechEx, a company providing research insights published a report that provides forecast about conductive inks and pastes for the next ten years. The main message is that demand will increase. The study provides a detailed analysis of 17 existing and emerging application sectors including silicon solar cells, RFID tags, touch screen edge electrodes, automotive, in-mould electronics, e-textiles, 3D antennas, 3D printed electronics, desktop PCB printers, ITO replacement, OLED lighting and others. These applications are the same as the ones on which BASMATI project is concentrating.

The project, developing a new value chain for conductive inks, will strongly benefit from this market traction. It makes the results of the projects extremely attractive for the industrial partners as there is a real market demand around the outputs of the project. The project develops a pilot line for the ink formulations ensuring large volume fabrication of new products with improved properties for printing application.

- Details

IDTechEx, a company providing research and business intelligence in the field of printed electronics and energy, published a report that provides forecast about Printed and Flexible Electronics in Automotive Applications for the next en years. According to the study, the market is expected to grow to over $5.5 billion dollars in the next decade, spearheaded by the projected growth of in mold electronics and OLED technologies.

BASMATI project focusing on the entire value chain of flexible printed electronics, will strongly benefit from this market opportunity. It makes the results of the projects extremely attractive for the industrial partners as there is a real market demand. The project develops a pilot line for the ink formulations ensuring large volume fabrication of new products with improved properties for printing application.

The two main technologies that will experience an important growth are OLED and in mold electronics (IME). OLED has become the premium display technology for many consumer products and the industry is now moving from glass substrates to plastic substrates following the trend towards flexible displays to be put into cars. IME are used in the formation of car overhead consoles. It is a multi-step process that utilizes establishes manufacturing techniques and existing tools. Graphical and functional inks are screen printed, subsequently thermoformed to the desired shape, and finally molded in the final step.

- Details

Printed Electronics is one of the fastest growing technologies in the world. It is of vital interest to industries as diverse as consumer goods, healthcare, aerospace, electronics, media and transit. It is allowing electronics to be used in places it has never been before and it is improving existing electronics and electrics. Printed Electronics Europe, attended by more end -users than any other, is your information and networking hub on the topic. The international exhibition, with more than 170 exhibitors, covers all the technologies throughout the entire supply chain across and across all the major component types.

This year, the event will take place from 27-28 April 2016 in Berlin, Germany as part of the IDTechEx Show! This is Europe’s largest end-user focused event! The only event focused on the commercialisation of printed, organic and flexible electronics.

Printed Electronics Europe is co-located alongside a series of synergistic events covering wearable technology, sensors, 3D printing, graphene, energy harvesting, and electric vehicles which makes this a truly unique and one of a kind event!

Sure, there are other printed electronics events on the 2016 calendar, however, Printed Electronics Europe in Berlin, is where you will meet customers and build business! There will be 2,500 high level attendees from business and technology fields, and 130 exhibitors from over 47 countries at the event.

Basmati project will be presented by Genes’Ink, member of the consortium.

- Details

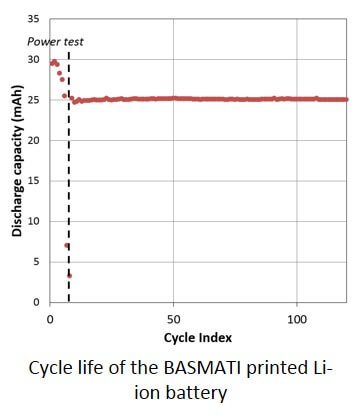

In a recent news, IDTechEx, a company providing research and business intelligence in the field of printed electronics and energy, presented the two main methodologies for developing flexible batteries. The first approach is to make the batteries very thin whereas the second one is about altering the structural design of the batteries. Printed batteries combine both approaches and allow a great flexibility of the device. This is exactly what the research project BASMATI is developing.

The BASMATI project focuses on entire value chain of flexible printed electronics where one application are printed batteries as power sources The project develops a pilot line for the ink formulations ensuring large volume fabrication of new products with improved properties for printing application.

A recent report from the aforementioned company forecasts a market of over $400 million in a decade, as thin, flexible and printed batteries be widely used in wearable and medical devices.

- Details

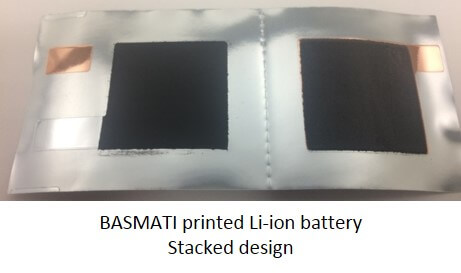

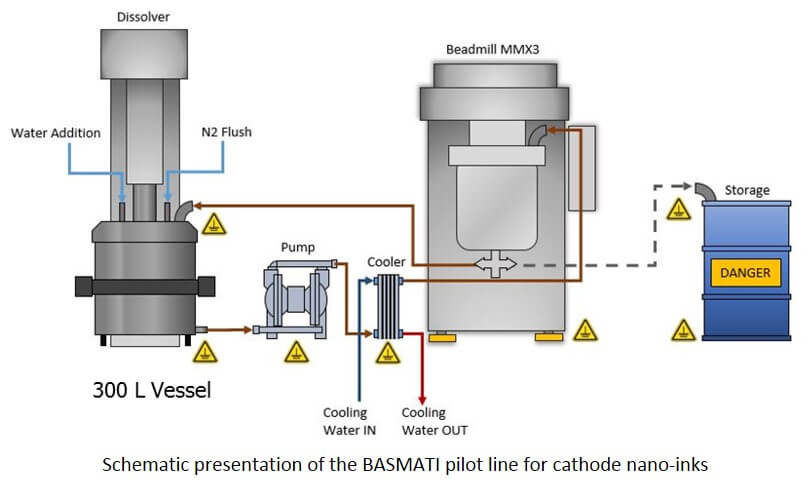

BASMATI 12M meeting, a H2020 funded research project on large scale nanoinks manufacturing for high throughput low cost flexible printed batteries, is holding its 12 months meeting in LEITAT facilities in Terrassa. The consortium is meeting for two days, from the 30th of November to the 1st of December, to discuss project objectives and progress made during the first year. The project is coordinated by umicore and develops active nanomaterial and electrochemical inks for printing technologies such as screen and inkjet printing.

More precisely, during this meeting, the consortium will discuss the criteria for selection of nanomaterials such as copper and nickel for conductive inks and LFP (Lithium iron phosphate) and NMC (Lithium nickel manganese cobalt oxide) for screen printing and inkjet.

BASMATI aims to (1) develop a network of large volume production Pilot Plants for conductive and electrochemical inks containing nanoparticles, (2) develop a new process line from lab to industrial production: these inks will be formulated, fabricated and up-scaled up to pilot conditions to offer full compatibility with high throughput, low cost printing processes such as inkjet printing and screen printing, and (3) develop pilot lines (~150-350 kg per day) for low cost inks dedicated to flexible printed batteries will be delivered by the project.